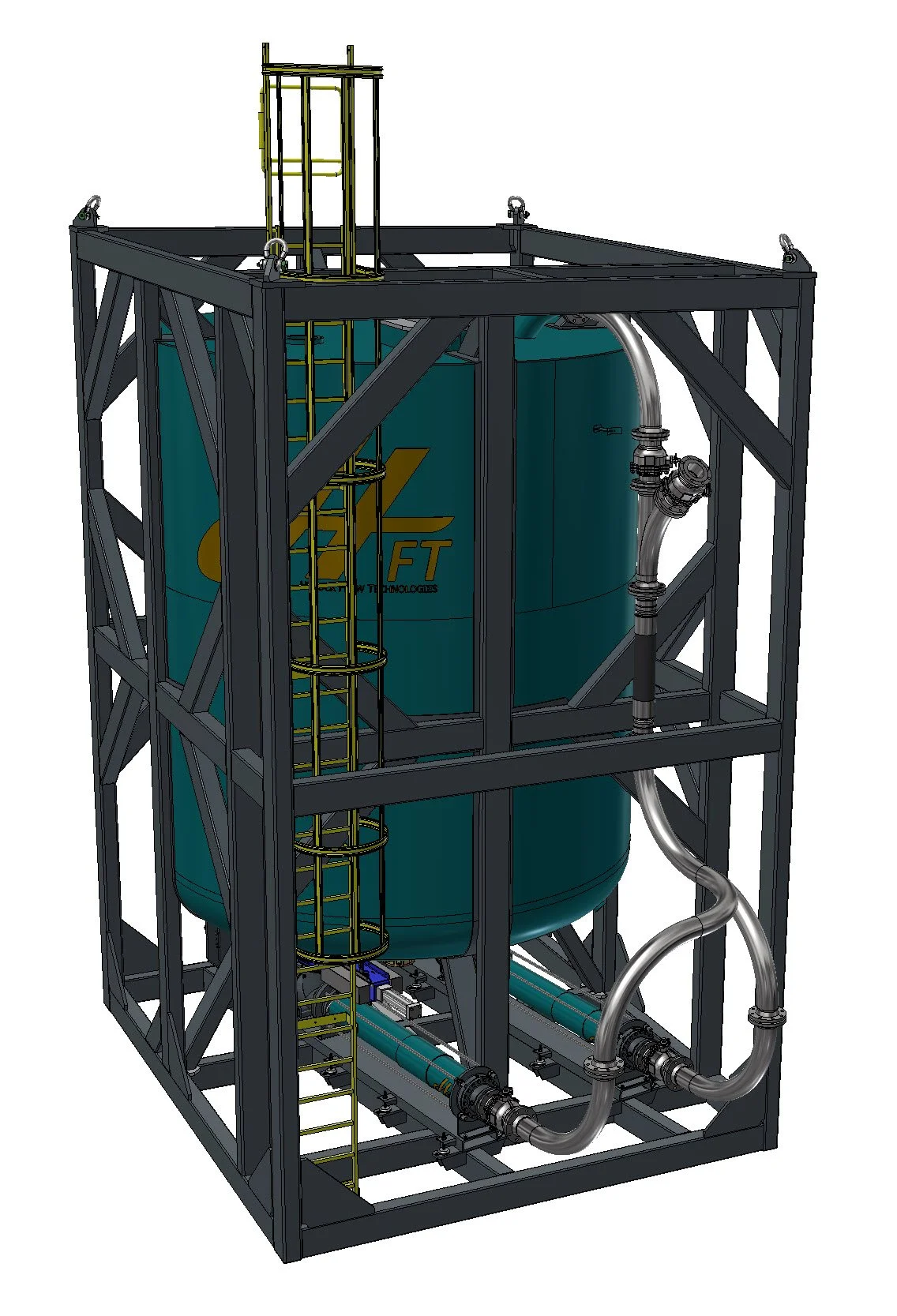

HFT-ICTU II Cuttings Transfer Unit

Controlled receiving and pump-feed is essential when handling drill cuttings from offshore drilling

We do this through our ICTU II with state-of-the-art sensorics and automation where exposure to crew and environment is secured at highest level.

Closed loop, high capacity and adequate redundancy secure performance

FLOW; MANAGED

Offshore drilling waste solutions

CUTTINGS & SLOP LOGISTICS enterring next gen

Focus on costs, CO2 reductions, safety (avoid crane lifts), and exposure to crew and environment (closed loop) motivate the industry to look for new ways of dealing with drilling waste going forward

HFT enable such efficient transfer and containment of cuttings and slop through our HFT-ICTU III and HFT-DCTC solutions;

- this being for transfer to storage, reinjection or processing offshore

HFT-Offshore novel drill-waste management

At HFT we follow drill cuttings from the drill-bit to completed processing

The offshore drilling market is more than overdue for a significant improvment in efficiency, cost and not least HSE in terms of how drilling waste (drill cuttings & slop) is being handled.

Closed loop, volume-efficient and secure transfer, containment and processing is the way forward for future offshore drilling for oil & gas. HFT is proud to lead!

DNV 2.7-3 Type A Receiving- and Storage

Tank clusters in crash-frames optional

When operations are less permanent, our CF-version DNV 2.7-3 Type A comes to play, as frequent transportation is better cared for

Backflip is larger footprint, more weight and corresponding resources

HFT-DCTC Drill Cutting Transfer & Containment solutions

Dedicated drill cutting and slop transfer and containment tank solutions for offshore O&G drilling on OSVs

Skips and containers are being outperformed both in efficiency, safety and environmental aspects by HFT-DCTC, in addition representing capacities for recovered oil and other liquids at demand

Space-efficient, closed loop, automated handling of offshore drilling waste

HFT-ICTU III Integrated Cuttings Transfer Unit

The HFT-ICTU III is bespoke designed for efficient and safe receiving and transfer of drill cuttings directly from the shale shaker, to on-rig storage tanks

The special design extended auger, and optimized inlet hopper allow for flow variations and density fluctuations typical to these applications in a good way.

We taylor these in a 2 or 3 pump configuration for redundancy and capacity in accordance with clients needs.

HFT-FLIC Feature Learning Integrated Control system

HFT-FLIC is our feature learning integrated control system which controls all our innovative solutions

Built on the latest architecture, hard-ware and creative software HFT-FLIC both monitor, control, learn and log all activities for our functions.

Built for open communication and integration at site and not least for full remote operations allow us to service all installation in a state-of-the-art way

HFT-ID&C Injection, Dosing & Cleaning module

HFT-ID&C modules for injection, dosing & cleaning are vital for the full automation of our transfer processes

Separation of various fluids with mixers for consistency control, and dedicated pump technologies to ensure performance is a required for smooth flow in challenging operations.

The compact and efficient design of our HFT-ID&C allow small footprint compared with performance, and with full compliance with DNV 2.7-1 regulations for safe handling offshore.

HFT-DCTC 125-III DC Shaker Receiver Pump

Built on the same unique, patented inlet flow geometry as our other DC pumps, these bespoke design HFT-DCTC 125-III Shaker Receiver Pumps secure functionality and smooth handling of drill cuttings including fully automatic flow regulation based on delivered volume at all times.

The special design extended auger, and optimized inlet hopper allow for flow variations and density fluctuations typical to these applications in a good way.

We taylor these in a 2 or 3 pump configuration for redundancy and capacity in accordance with clients needs.

HFT-DCTC 50x4

Receiving- and Storage tanks for efficient, closed-loop transfer and containment of offshore drilling waste such as drill cuttings and slop

HFT-DCTC Storage Tanks

Dedicated drill cutting and slop transfer and containment tank solutions for offshore O&G drilling

Space-efficient, closed loop handling of offshore drilling waste

HFT-DCTC 125-III DC Pump

HFT Dedicated, special design Progressing Cavity pump for transfer of drill cuttings, and other challenging fluids

ATEX classed, hydraulic drive with speed regulation

HFT-CAVA 120 800 E Vacuum Units

HFT-CAVA 120-800-E electrically driven vacuum unit

Designed for efficient DC lift from skips a.e. to our HFT-DCTC system, this unit complement our HFT- CAVA 120-800-D diesel driven machine

Zone II / Norsok Z-015 compliant, and DNV 2.7.3 offshore handling codes allow for both temporary and fixed installation

Offshore certified, ATEX approved

HFT-CRIU 450/750 Cutting Reinjection Units

As reinjection of cuttings into offshore formations become more relevant, our HFT-CRIU 450 / 750 units completes our scope for the drilling community.

Electric, hydraulic or diesel driven alternatives are available – both for safe and ATEX-areas

HFT-CAVA 120 800 D Vacuum Units

Diesel- powered high capacity vacuum units for multiple services, like drill cutting transfer to DCTC

Offshore certified, ATEX approved

HFT-DCTC 705 EPU

These Eco Power Units are purpose-built for efficient operations of all DCTC-function

A 2+1 pump configuration, frequency cotrolled to save energy, and allow for smooth ramp-up of power as required.

Offshore certified, ATEX class

HFT-FWTC solutions for Aqua-culture waste

The HFT-FWTC contribute to efficient waste handling

Focus is high on the waste-side of the fish farming business, and represent a large potential if handled well

Biogas-extraction would be one way forward, and HFT contribute with efficient separation of solids from liquid, closed-loop transfer and storage / curing tank cluster being for processing or further logistics